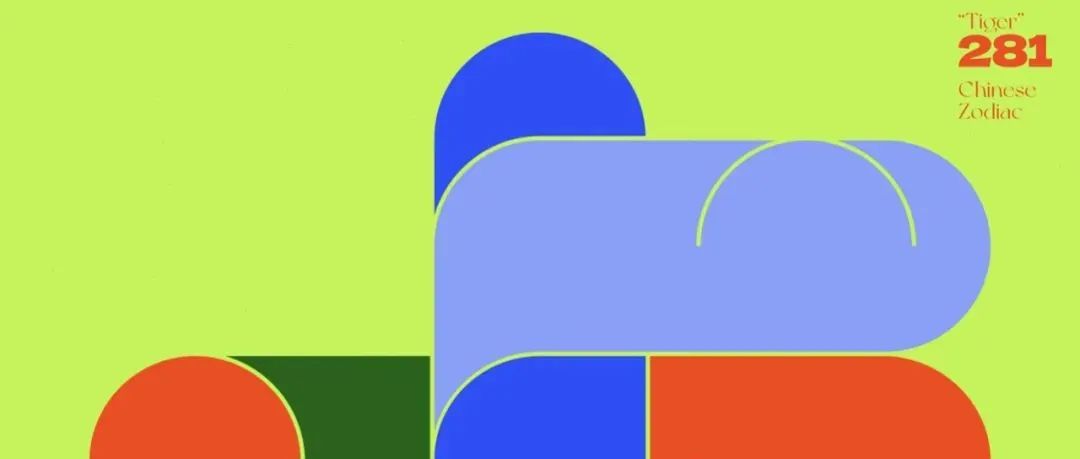

for WonderGlass

A furniture collection designed for WonderGlass, a manufacturer and expert of Venetian glass.

为威尼斯玻璃制造商和专家WonderGlass设计的家具系列。

The company excels in glass casting with a special technique of removing pliable material out of the mold to further process it by hand. The design ofthe new collection takes advantage of this method and the viscosity of the glass.

该公司在玻璃铸造方面的优势在于,它采用了一种特殊的技术,将易弯曲的材料从模具中剥离出来,然后用手工进一步加工。新系列的设计利用了这种方法和玻璃的粘度。

In the making process molten glass is first poured into a square frame, where anumber of craftsmen simultaneously even out the surface using iron trowels. The glass gradually cools and upon reaching a certain pliancy, it is moved and placed onto a U-shaped mold or its inverted shape, allowing the glass to slowly sink or stretch to create a beautiful arch. Even during this shaping process,the craftsmen use tools to shape the arch, making sure there are no bends orcracks.

在制作过程中,首先将熔融的玻璃倒入一个方形框架中,许多工匠同时使用铁锹将玻璃表面弄平。玻璃逐渐冷却,在达到一定的柔韧性后,将其移动并放置到u型或其倒立的形状上,让玻璃慢慢下沉或伸展,形成一个美丽的拱形。即使在这个成形过程中,工匠们也会使用工具来塑造拱门,以确保没有弯曲或裂缝。

This curving glass technique is used to design armchairs, tables, flower vases,and more. Since the arches and curves are created by the glass’s own weight and viscosity, the collection was named “melt”.

这种弯曲的玻璃技术被用于设计扶手椅、桌子、花瓶等。由于拱形和曲线是由玻璃本身的重量和粘度造成的,所以这个系列被命名为“熔体”。

melt

shape of gravity

申明:

内容版权自Nendo官网

我的翻译仅作参考,如觉翻译不妥,请跟我联系,探讨后可做修改,谢谢!

本文来自微信公众号“佐藤大Nendo设计”作者:Mao Mouth(ID:gh_ce2c42193789)。大作社经授权转载,该文观点仅代表作者本人,大作社平台仅提供信息存储空间服务。