Connecting you to the Wood Design

—

TIANFU

Agricultural Expo

专访 木结构工程 StructureCraft

Lucas Epp 先生

专注于 Mass Timber 领域的创新工程项目

StructureCraft 副总裁及工程总监

拥有在北美、英国、新西兰和中国等地

十五年工作经验的资深结构工程师

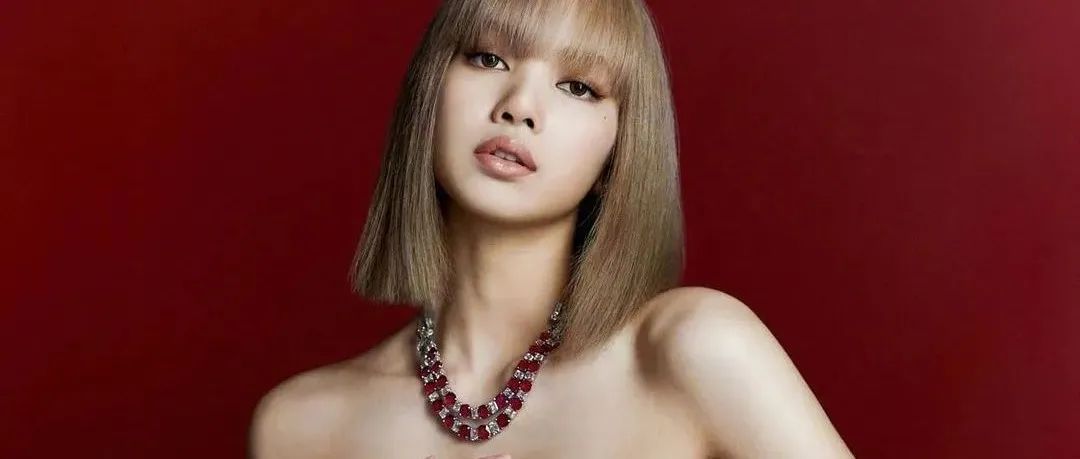

D|W:这是您与中国建筑设计研究院崔恺院士的第二次合作,是因什么机缘而开始的合作?This is the second time you collaborated with Mr. Cui Kai. How did this journey start in the first place?

L.E :StructureCraft 与崔恺院士已经认识八年多了。那时候我和父亲一起来到北京,崔恺院士带我们参观了他的工作室并展示了他的建筑作品,我们很敬佩崔恺院士对于推广绿色建筑的执着和坚持。其实中国使用木建筑已经有悠久的历史了,很多寺庙都是用木头建成。但过去使用的木材和现在的不一样,那时是整根木头砍下来,需要大量完整和巨大的树木。现在我们已经没有那么多巨大的树木了,所以才产生了今天的工程木材,这对原材料的要求降低了很多。我们只需要小块木,然后用胶合木(Glulam)或者交叉层压木材(CLT)的方式,就可以把小块木头变成可塑性强、并可用于建筑的木材材料。Our firm StructureCraft has known Mr. Cui Kai for almost eight years now. My father and I visited Mr. Cui Kai in Beijing at that time. He showed us his studio as well as his designs and works. We really appreciated his dedication and devotion in promoting green architecture. China has a long history of using wood as constructural material. I have seen many old temples built with wood. In the past, huge tree logs were chopped down and used as a whole. Nowadays, we don't have big trees like before. Therefore we have engineered wood, which does not require such big piece of wood. All we need is just small pieces of wood. By using Glulam or CLT, these wood pieces can be turned into ideal materials for construction, no matter big or small projects.

© StructureCraft

崔恺院士有了农博园的构思后,专门飞来加拿大,在我们的工作室展示他的想法。因为项目的挑战性和独创性,在初期遇到了一些困难。本地团队成员更倾向于使用混凝土和钢结构,但崔恺院士说服他们,并坚持下来,这才有了今天美丽的天府农博园项目。When Cui Kai presented his idea in our studio early on in the project, it encountered certain limitations locally due to its challenge and ingenuity. Several local team members preferred to use concrete and steel structures. But the academician persuaded them and persevered, resulting in the beautiful project we see today.

D|W:为什么会接受如此具有挑战性的建筑设计?Why would your firm take on such a bold and challenging design?

L.E :之前在太原,我们就和奥地利建筑事务所 Delugan Meissl 一起合作过,建造了太原植物园。该项目由三个直径从43米到88米不等、高度从12米到30米不等的木制圆顶组合而成,其中最大的一个圆顶是世界上最长的净跨木制壳结构。这个项目赢得了许多杰出的奖项,包括结构工程师协会颁发的结构大奖,给了我们很大信心,使我们明确了用工程木建造高难度结构存在着无限可能。We have collaborated in China previously, working with Delugan Meissl on the Tai Yuan Botanical Garden, which features 3 domes ranging from 43m to 88m in diameter and from 12m to 30m in height. The largest of the three domes is the longest clear-span timber gridshell (non-triangulated) in the world. It has won many prominent awards, including a Structural Award from the Institute of Structural Engineers. We realized the great potential of what timber can achieve as a structural material, which boosted our confidence that we were on the right path.

© StructureCraft

©CreatAR Images

D|W:作为亚洲最大的木结构建筑,有什么创新之处?As the largest timber structure in Asia, what are the structural innovations?

L.E :除了整体使用木构件外,还结合了钢构件的使用。这种结合保证了主体结构是木结构的基础上,同时很好地利用钢材的特性和优势。农博园的另一个结构创新是每个桁架网都是独立的,彼此不相连。这种情况下,整个桁架就可以预制成不同的子构件,而不需要整体连接在一起,并可以在到达现场后再与其他构件灵活组装。这种结构创新还保证了现场 2-3 毫米的施工公差,比钢结构现场施工准确得多。In addition to the overall use of wooden components, the use of steel components is also integrated. This method ensures that the main structure is wood, while taking advantage of the characteristics and advantages of steel. Another structural innovation of the Expo is that each truss web is independent and not connected to the next. In this way, the entire truss can be prefabricated into different sub-components, without the need to be connected together as a whole, and then assembled with other components after arriving at the site. This structural innovation also ensures a construction tolerance of 2-3mm on site, which is much more accurate than the on-site construction of steel structures.

D|W:疫情期间无法亲临现场的情况下,您如何同时统筹三大洲团队?设计、生产和建造过程中遇到哪些困难, 如何克服?Due to the ongoing panemic, how do you manage to ensure quality control when you were not able to be physically present?

L.E :一般情况下,每一个项目我都会亲自到场监督,由于签证和隔离问题,这还是第一次我无法亲身到场。中国籍工程师在其中发挥了很大作用,他们代替我到达现场监督,每天从早到晚轮流在工地拍摄图片传送到加拿大办公室。我们也运用了许多高科技,例如无人机操控,还有特制建筑软件,可以跟踪建筑上的所有细节,并且把现场的每一个部位都和我们的草图连接起来,这样就确保了即便我不在现场,所有细节都能过关。This is the first time ever that I could not be on site for a project. Due to visa and quarantine problems, we had to instead send our engineers who were Chinese nationals. Thanks to them, they were on the construction sites 24/7 and reported back to the office in Canada on a daily basis. We also started to rely on available technologies, like drones, and special design software, which can track every single detail on the construction and match points to our oringinal sketches. In this way, we can ensured quality control down to the every details.

D|W:四川靠近地震带且当地湿度大,在项目建造过程中,如何预防这些自然条件所可能带来的问题呢?Geographically speaking, Sichuan is located near an earthquake zone and has high humidity.What measure did you take to prevent such potential hazard?

L.E :我们的三角桁架的设计是灵活的,与地面连接的底部可以扩大,能够在地震时保持稳定。至于潮湿气候,其实木头本身就含有大量水分,所以这种建材本身天天就在和湿度打交道。木材出现发霉或腐烂,主要是水分长久停留在表层。因此,我们只要在设计上考虑到这个因素,就可以避免发生发霉和腐烂的情况。The design of our triangular section truss is flexible, and the connection with the ground can expand, so as to be stable in the event of an earthquake. As for humidity, wood is a material that contains lots of water in itself, which is not something new. The reason why mold and rotting happens is becuase water stays for a long time on the surface. When we design, we take those elements into consideration and prevent water sitting on surface for long period of time.

© StructureCraft

观点 Wood For Future

D|W:你怎么看待木建筑的未来?What is your take on a future of timber structures?

L.E :木建筑肯定大势所趋。其实木建筑存在已久,只是被我们遗忘了罢了,是时候我们应该重新发掘木建筑的优势。据我所知,北美和欧洲的许多建筑师都开始把工程木材作为主要建筑材料,并且有可能建造出更多更高的木结构建筑,毕竟工程木材已经给这些构想提供了可能性。It is definitely a trend. Wood as building material has long been existing. It is time we rediscover the advantage of building with wood. As far as I know, a lot of architectures in both North America and Europe have started using more and more wood as their prime structural material, since we are all awared that wood has been use in larger and taller buildings. There is huge potential that is waiting for us to unlock.

© StructureCraft

D|W:中国是北美以外的最大市场吗?你怎么看待木建筑在中国的未来?Is China the largest market outside of North America? What is your thoughts on timber structure's future in China?

L.E :的确,中国是北美以外最大的市场。中国现在最缺的是本地化生产的工程木材,现在的发展水平离达到自产自用的标准还落后5-10年。欧洲在这个领域是最领先的,比北美要早20年开始研发,这也是为什么我们这次的木材从欧洲采购,再经由铁路运输到中国。因为与崔恺院士的合作,我们也开始和更多中国本土的行业专家合作,例如同济大学,中国建筑设计研究院,给他们提供我们的经验和技术,希望与他们一起快速发展。China is definitely the largest market outside North America. But what is missing is local manufacture which can produce good quality woods that can be used in large constructions. At present, the manufactury quality and level in China is 5-10 years lagging behind world standard. In this regard, Europe is leading, which is 20 years ahead of North America. That is why we purchased wood from Europe when building Tian fu. All the wood was shipped to China by rail. Because of Mr. Cui Kai, we have started projects collaborating with other key Chinese industry experts, such as Tong Ji University and China Architecture Design & Research Group. By sharing our knowledge, we hope local industry stakeholders can gain the skills and develop together with us.

© StructureCraft

展现出世界级创新设计与工程水平的中国天府农业博览园顺利落成,并将在今年春天迎来盛大的开幕,也期待未来越来越多的世界一流木结构项目在中国涌现。

Design|Warehouse 2015年创建于荷兰,基于拥有30万专业建筑师、设计师粉丝的Instagram发展而来的国际媒体与社群平台。DW关注 “碳中和” 下的未来人居环境和可持续建筑,致力成为最好的木建筑国际媒体。

本文来自微信公众号“DesignWarehouse”(ID:gh_114e3e419411)。大作社经授权转载,该文观点仅代表作者本人,大作社平台仅提供信息存储空间服务。