2008.04

for LEXUS

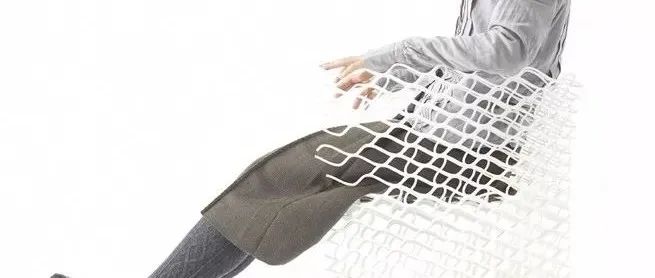

The dense and atomic structure of a diamond efficiently disperses strength and light throughout the material, giving diamonds their singular hardness and shine. We designed a “strong but flexible” structure that used this atomic array as a motif, and wanted to devise a chair that would respond to pressure by absorbing rather than resisting it, and had the suppleness of human organs or muscles.

金刚石的致密和原子结构有效地在整个材料中分散强度和光线,使钻石具有独特的硬度和光泽。我们设计了一种“强而灵活”的结构,将这种原子阵列用作主题,并且想要设计一种能够通过吸收而不是抵抗压力来应对压力的椅子,并具有人体器官或肌肉的柔软性。

We created such a structure through powder sintering rapid prototyping technology that uses a laser to transform polyamide particles into a hard mold based on 3D CAD data. The RP technology let us add thickness where users need support, and to carve away the material into a thinner, more flexible and responsive thickness in places where users want comfort, allowing one material to serve multiple purposes. There is a limit to the size of an object an RP machine can produce, so we designed the chair in two pieces that snap together like a puzzle, and attached them after each piece had hardened. This not only let us control cost and production time, but also, since the pieces are cast at the same time, eliminated the problem of parts not fitting together exactly during assembly because any shrinkage or distortion due to heat occurs at the same time and the same rate.

我们通过粉末烧结快速成型技术创建了这样一种结构,该技术使用激光将聚酰胺颗粒转化为基于3D CAD数据的硬模具。RP技术让我们可以在用户需要支撑的地方增加厚度,并在用户需要舒适的地方将材料切割成更薄,更灵活和响应更厚的厚度,从而使一种材料可用于多种用途。RP机器可以生产的物体的尺寸是有限的,所以我们将椅子设计成两块,像拼图一样折叠起来,并在每块硬化后将它们连接起来。这不仅让我们控制成本和生产时间,而且由于这些部件同时铸造,消除了部件在装配过程中不能精确配合的问题,因为同时发生由于热量引起的任何收缩或变形 同样的速度。

We’re not planning to mass-produce the chair, but since it only takes five to six days to produce, a manufacturer would not have to worry about keeping it in stock, and overseas orders could be filled by sending data overseas for production on a local RP machine, drastically cutting shipping time and cost. In other words, the diamond chair project showed us that in the near future, we may well solve problems that have long plagued the furniture industry.

我们不打算大规模生产这种椅子,但由于生产只需要五到六天,制造商就不必担心库存,海外订单可以通过向海外发送数据来填补。一台本地RP机器,大大缩短了运输时间和成本。换句话说,钻石椅项目告诉我们,在不久的将来,我们很可能会解决长期困扰家具行业的问题。

申明:

内容版权自Nendo官网

未经许可,严禁转载,谢谢合作

我的翻译仅作参考,如觉翻译不妥,请跟我联系,探讨后可做修改,谢谢!

本文来自微信公众号“佐藤大Nendo设计”(ID:gh_ce2c42193789)。大作社经授权转载,该文观点仅代表作者本人,大作社平台仅提供信息存储空间服务。